DMT ENCOS Thermal Separation Processes

The design and application of thermal separation processes is a main area of expertise for DMT ENCOS. Only a few engineering processes do not require thermal separation processes.

What do we mean by Thermal Separation Processes?

In thermal separation processes, mixtures of substances are generally separated by the addition of a separating agent, in which the thermodynamic equilibrium between the phases involved is re-established in the desired direction. Efficiency and separation efficiency are decisively increased by the principle of multistage, as it is implemented for example in separation columns. DMT ENCOS has extensive expertise in the specific industrial Domains of:

- Distillation / rectification

- Gas scrubbing / absorption

- Stripping / desorption

- Vacuum drying

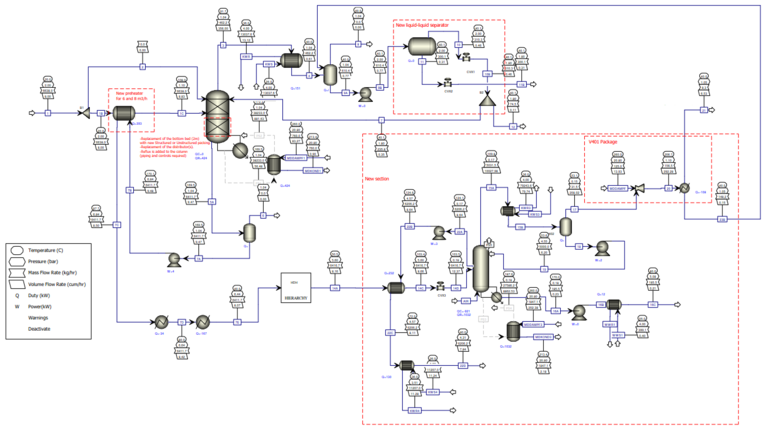

Our solid knowledge in the field of multiphase thermodynamics allows us to efficiently design and plan even complex separation tasks using powerful process simulation systems such as PRO II or ASPEN-Plus. Our basic & detail engineering references range from projects for the petrochemical industry, refineries, to the food industry and many more, such as:

- Basic and detail engineering of distillation columns for the separation of fatty alcohol mixtures, including the periphery

- Flash columns for extract-mix evaporation including associated heat integration

- Amine scrubbers for H2S separation from acid gases

- Distillation columns for the separation of amine mixtures

- Product strippers for separating solvent residues from lubricating oil products

- Vacuum dryers for thermal treatment of edible oils in spray columns

We are looking forward to your inquiry.

Buxtehuder Straße 29

D-21073 Hamburg

Tel.: +49 40 751158-0

Fax: +49 40 751158-30

sales@encos.de