Mechanical Engineering

Mechanical Engineering is subdivided into specific technical competencies, which at DMT ENCOS are also closely connected in organisational terms with process technology.

- Mechanical engineering for rotating equipment

- Static Equipment

- Installation and steel construction planning

Mechanical Engineering - Rotating Equipment

Detailed engineering with reference to the rotating equipment sets the course for the entire life cycle of the machinery and systems to be planned. This is why our engineers focus on key criteria such as:

- Durable materials

- Robust construction

- Easy maintenance

- Energy efficiency

- API-compliant barrier oil systems

- ATEX conformity

- Minimum sound emission

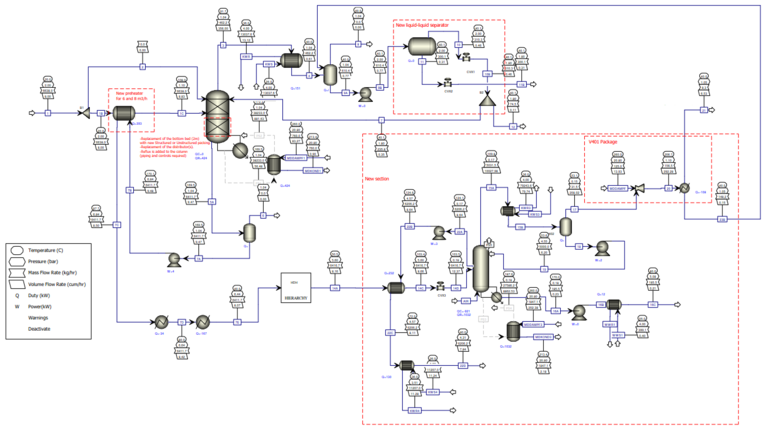

Regarding the process flexibility of the machinery and plants, the determination and selection of control options also plays a decisive role. This is where close cooperation with the specialist disciplines of process technology, electrical engineering and instrumentation at DMT ENCOS beginns.

Mechanical Engineering - Static Equipment

In line with its core competencies in the field of chemical and thermal process engineering, DMT ENCOS also covers the technical requirements in mechanical as well as in plant engineering for static equipment. Based on the process-engineering requirements, the following factors are used in:

- Material selection

- Coating system

- Surface quality

- Focus on customer-specific design Guidelines

Details / Specification

DMT ENCOS prepares detailed specifications for you in the form of design drawings for process equipment, such as:

- Absorber columns, stripper columns, distillation columns and partition wall columns

- Tubular reactors, fixed bed reactors, stirred tank reactors

- Shell-and-tube heat exchangers, double-tube heat exchangers

- Phase separation containers, storage containers, flash containers, slop containers

- Separation and immersion containers for safety and emptying equipment systems (blow-down system)

Typical design adaptations of all other installations (so-called internals) are taken into account and applied:

- Special processes (supports) for process bottoms, structured packings, fillers

- Demister, droplet separator packages

- Catalyst beds

- Liquid and vapour inlet systems for process columns and phase separation vessels

Please Note

DMT ENCOS does not act as an equipment manufacturer and therefore does not create any apparats manufacturing drawings. This makes the following work steps of mechanical engineering in the procurement phase particularly important:

- Checking, commenting and approval of production drawings

- Coordination of the audit by the departments of installation planning, piping, process technology, istrumentation and control